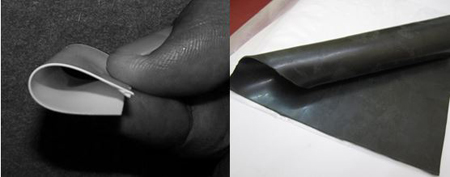

This technology provides for manufacturing flexible lead-free formulations for X-ray shielding. It involves an easy solvent-free procedure for synthesis and the sheets obtained by this technology are highly flexible and stretchable. The high filler loading in these formulations provides excellent X-ray attenuation which can be tuned depending on the desired application. The sheets are also easily processable and can be readily shaped into desired shape such as apron or thyroid shield as needed for the application. The technology requires easily available processing tools in small/ medium/ large scale polymer industries. The raw material required for developing these formulations are commercial grade chemicals easily available with local vendors.

Most of the present day medical imaging techniques are based on X-rays which necessitates the use of X-ray shielding for technicians and medical workers involved in these procedures on regular basis. The medical X-ray shielding, presently, is based on Pb (lead) and Pb-based compounds. However, the harmful biological effects of lead are well known and documented. Lead is toxic, and has associated manufacturing and disposal problem. Also, the shielding garments based on lead are heavier and non-stretchable that leads to lesser user compliance. In order to circumvent the problems associated with lead, the flexible lead-free formulations have been developed for X-ray shielding. These have been developed using an easy solvent-free procedure which ensures good X-ray attenuation (shielding) behavior due to higher filler loading achieved. The shields developed by these formulations are highly flexible and stretchable. They are easily processable and can be readily shaped into desired shape such as apron as per the application. In addition, these formulations can also be tuned for the X-ray attenuation (shielding) behavior as per the desired applications.

X-rays have extensive applications in the field of medical imaging. However, due to continuous exposure, the technicians and health-workers are advised to use X-ray shielding. Most of the radiation shielding apparels are based on lead and lead-based compounds. Lead is cumulative toxicant and affects multiple body systems. It can cause severe damage to brain and kidney and hence lead has associated manufacturing and safe disposal problems as well. In addition, lead-based shielding is heavy, non-stretchable and hence it is not very conducive to long-term usage which leads to lesser user compliance. In order to circumvent the problems associated with lead, the flexible lead-free formulations have been developed for X-ray shielding. The synthesis of these formulations has been carried out using a facile solvent-free procedure. The synthetic procedure has been designed to ensure high filler loading to achieve good X-ray attenuation (shielding) behavior. The sheets obtained by processing the formulations are highly flexible and stretchable. They can be easily processed and readily shaped into desired shape such as apron or thyroid shields as per the application. There is also a scope of tuning the X-ray attenuation (shielding) depending on the final application.

The X-ray attenuation is primarily a function of Z (atomic number) of the stopping/shielding medium due to the higher probability of interaction by photoelectric effect which increases with increasing Z. These formulations consist of high loading of high Z filler that bestows it with desired attenuation behavior. The other important ingredients based on carbon make the formulation sturdy and superior in terms of mechanical behavior and better wear and tear. The mixing and synthesis protocol has been suitable developed to obtain homogeneous stretchable formulations.

* It may please be noted that these instruments can be replaced by other already available alternatives (for the required purpose) in the industries which are involved in polymer processing.