Triode Sputter Ion Pumps operate in the pressure range 10 –3 to 10-10 Torr. These pumps are used to create UHV in charged particle accelerators, surface analytical spectrometers, mass spectrometers etc. Technology for 35, 70, 140 & 270 LPS capacity are available.

It is an import substitute product, and has wide range of applications in the field of Ultra high vacuum systems like charged particle accelerators, surface analytical equipment, mass spectrometers etc. These pumps have no moving parts and provide very clean operation. The operating pressure range is 10-3 to 10-10 torr. This technology is available for Transfer of 35, 70, 140 & 270 lps capacity pumps.

These pumps are used to create UHV in charged particle accelerators, surface analytical spectrometers, mass spectrometers etc.Technology for 35, 70, 140 & 270 LPS capacity pumps.

Easy maintenance - Dismantle type body feature except for 35 LPS design

INTRODUCTION

The triode sputter ion pumps are employed to create hydrocarbon-free ultra high vacuum. They utilise the high intensity cold cathode discharge produced in a magnetic field to sputter a highly reactive metal. The reactive metal layer called getter film combined with the active gas molecules such as hydrogen, nitrogen, oxygen, water vapour etc to form low vapour pressure stable compounds, thus reducing the number of gas molecules and hence gas pressure in the system volume.

These pumps operate in the pressure range 10 -3 to 10-10 Torr. They do not require the services of a backing pump continuously but only need initial forepressure of 10-3 Torr. The discharge current being proportional to the background pressure, the pumps also serve as pressure measuring gauges.

These pumps have higher pumping capacity for inert gases compared to its predecessor diode sputter ion pump. These pumps can be mounted on a system in any orientation.

The triode sputter ion pumps are used to create ultra high vacuum in charged particle accelerators, surface analytical spectrometers, mass spectrometers etc. R&D institutes, universities may require such types of pumps.

| Pump Type | TSIP-35 | TSIP-70 | TSIP-140 | TSIP-270 | |

| Pumping Speed (1/s) | For N2 | 35 | 70 | 140 | 270 |

| For Ar | 8 | 16 | 32 | 60 | |

| Starting Pressure (Torr) | < 5x10-3 | < 5x10-3 | < 5x10-3 | < 5x10-3 | |

| Ultimate Pressure (Torr) | 5x10-10 | 5x10-10 | 5x10-10 | 5x10-10 | |

| Baking Temp.With magnets (°C) | 250 | 250 | 250 | 250 | |

| Connecting flange NB | 63 CF | 100 CF | 150 CF | 150 CF | |

| Magnetic Field (Gauss) | 1200 | 1200 | 1200 | 1200 | |

| Stray magnetic field at Flange (Gauss) | < 2 | < 2 | < 2 | < 2 | |

| No. of sputtering Assemblies | 1 | 2 | 4 | 4 | |

| Max. Operating Voltage (kv) | 6.2 | 6.2 | 6.2 | 6.2 | |

| Short Circuit Current (mA) | 100 | 200 | 500 | 750 | |

| Weight (kg.) | 20 | 33 | 52 | 82 | |

This supply can be used with Triode Sputter Ion Pumps having pumping speeds up to 140 lps and for Thin film deposition by DC magnetron sputtering technique. Sputter ion pumps find extensive use in high vacuum systems where a “clean” vacuum is desired. They are used in scanning probe microscopy and other high-precision apparatuses.

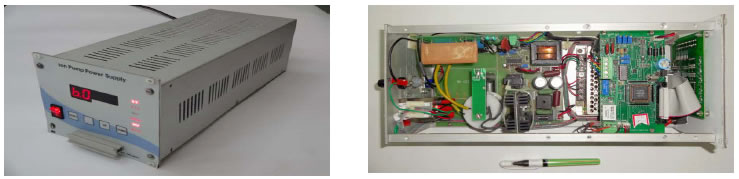

Conventional Sputter ion pump power supplies tend to be heavy and bulky as they operate on the mains frequency viz. 50Hz. The compact switched mode triode sputter ion pump power supply made in BARC is based on a half bridge dc to dc converter operating at 20kHz resulting in a drastic size reduction of around 75% over conventional mains frequency operated ion pump power supplies. Our compact SMPS triode sputter ion pump power supply is rated for an open circuit voltage in the range of -6kV to -7kV with a short circuit current rating of 200mA. This supply can power triode sputter ion pumps of ratings up to 140 liters / second. A microcontroller circuit is used to display the various parameters, implement the Trip logic and provide a PC interface

Sputter ion pumps find extensive use in high vacuum systems where a “clean” vacuum is desired. In contrast to other common UHV pumps, such as turbo molecular pumps and diffusion pumps, ion pumps have no moving parts and use no oil. They are therefore clean, need little maintenance, and produce no vibrations. These advantages make ion pumps well-suited for use in scanning probe microscopy and other high-precision apparatuses.

The compact switched mode triode sputter ion pump power supply made in BARC is based on a half bridge dc to dc converter operating at 20kHz resulting in a drastic size reduction of around 75% over conventional mains frequency operated ion pump power supplies. This supply can be used with Triode Sputter Ion Pumps having pumping speeds up to 140 lps and for Thin film deposition by DC magnetron sputtering technique.

One electronics engineer and one technical assistant with general electronics test and assembly facility is sufficient. Experience in working with high voltage devices is expected.

Conventional Sputter ion pump power supplies tend to be heavy and bulky as they operate on the mains frequency viz. 50Hz. Our design is based on the proven leakage inductance high frequency transformer followed by a rectifier cum voltage multiplier. This power supply is based on a half bridge dc to dc converter operating at 20kHz resulting in a drastic size reduction of around 75% over conventional power supplies. This in turn results in a compact vacuum system with a smaller footprint. Our compact switched mode triode sputter ion pump power supply is rated for an open circuit voltage in the range of -6kV to -7kV with a short circuit current rating of 200mA. This supply can power triode sputter ion pumps of capacities up to 140 liters / second. A microcontroller circuit is used to display the various parameters, implement the Trip logic and provide a PC interface.

Sputter ion pumps find extensive use in high vacuum systems where a “clean” vacuum is desired. In contrast to other common UHV pumps, such as turbo molecular pumps and diffusion pumps, ion pumps have no moving parts and use no oil. They are therefore clean, need little maintenance, and produce no vibrations.

The compact switched mode triode sputter ion pump power supply made in BARC is based on a half bridge dc to dc converter operating at 20kHz resulting in a drastic size reduction of around 75% over conventional mains frequency operated ion pump power supplies.

A direct mains operated half bridge chopper feeds power to a ferrite core leakage inductance transformer, the output of which is boosted by a rectifier cum voltage doubler to generate a voltage in the range of -6kV to -7kV. A microcontroller based circuit is used to display the various parameters, implement the Trip logic and provide a PC interface.

| 1 | Output voltage | -6 to -7kV @ open circuit |

| 2 | Output current | 200mA @ short circuit |

| 3 | Type | Switch Mode Power Supply |

| 4 | Processor | : NXP make P89V51RD2FA |

| 5 | Display | 7 segment Digital display 2 digits for mantissa & 3 digits for exponent |

| Selectable display of | a) Voltage: 0 – 10kV FS b) Current: 0 – 200 mA in 5 decade ranges c) Pressure:10-4 to 10-9 Torr d)Pressure:10-4 to 10-9 mbar |

|

| 6 | Membrane keypad | 4 x 1 Keys RESET, H V ON/OFF Scroll up and Scroll Down |

| 7 | Protection | Overpressure Trip set at 1 X 10-3 T 30 Min Timer Based Trip set at 1 X10-4 Torr |

| 8 | Input | 230 VAC ± 10%, 50Hz, 1Φ |

| 9 | Trip interlock | A potential free contact preset to 5 X 10-5 Torr. Contact rating 230V, 1 Amp |

| 10 | H. V. Termination | : Lemo make 2 Pin HV connector |

| 11 | Serial Interface | : RS 232 Modbus RTU protocol |

| 12 | Output Cable | Shielded 10 kV Teflon insulated HV cable |

Special Instruments Required

MANPOWER