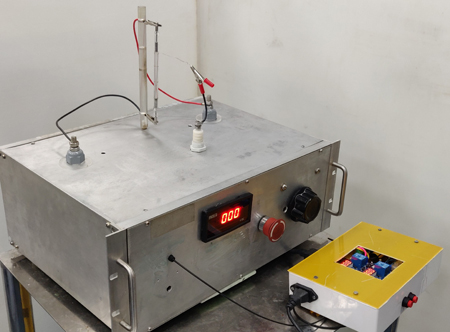

Pulsed UV Disinfection System produces pulsed, high energy, broad spectrum of UV lights (200- 400 nm). Uniqueness of the system is its broad UV spectrum which can kill various pathogens having different DNA absorption peaks unlike the conventional UV-C lamp which produce a single peak of 254 nm. The system is tested at 1 meter which can kill 99.998% of pathogen when exposed for only 5 minutes. The system can be used for sterilization of medical devices, food sterilization in food industries and can be installed in any transport devices like car, bus for disinfection purposes.

Pulsed UV Disinfection System produces pulsed, high energy, broad spectrum of UV lights (200- 400 nm). Uniqueness of the system is its broad UV spectrum which can kill various pathogens having different DNA absorption peaks unlike the conventional UV-C lamp which produce a single peak of 254 nm. The system is tested at 1 meter which can kill 99.998% of pathogen when exposed for only 5 minutes. The system can be used for sterilization of medical devices, food sterilization in food industries and can be installed in any transport devices like car, bus for disinfection purposes.

Pulsed UV Disinfection System produces pulsed, high energy, broad spectrum of UV lights (200- 400 nm). Uniqueness of the system is its broad UV spectrum which can kill various pathogens having different DNA absorption peaks unlike the conventional UV-C lamp which produce a single peak of 254 nm. The system is tested at 1 meter which can kill 99.998% of pathogen when exposed for only 5 minutes. The system can be used for sterilization of medical devices, food sterilization in food industries and can be installed in any transport devices like car, bus for disinfection purposes.

Conventional methods for sterilization of medical devices like wet/dry heat, irradiation, chemical gases can be negatively altered the material properties which influence the physical and biological performance of the medical device leading to material failure. Similarly in food industries, traditional thermal-based food-processing methods for microbial inactivation changes in food matrix; such as structural alteration of proteins, production of free radicals, affecting the functionality of food and flavor, destruction of colors and vitamins. Emerging technologies like UV light sterilization/disinfection can suppress the drawbacks of the conventional methods used in hospital and food industries .The developed pulsed UV disinfection system which Produce pulsed, high energy, broad spectrum of UV lights (200-400 nm). Uniqueness of the system is its broad UV spectrum which can kill various pathogens having different DNA absorption peaks unlike the conventional UV-C lamp which produce a single peak of 254 nm. Pulsed UV light has many advantages over continuous UV light in terms of microbial inactivation efficacy, penetration ability, and lamp safety. This kind of Pulsed UV disinfection systems are already tested in abroad for quickly deactivate SARS-CoV-2, MRSA, C. diff, VRE and other pathogens.

Precaution: During operation the exposure area should be free from human beings as UV radiation produced by the system is harmful to skin and eye.