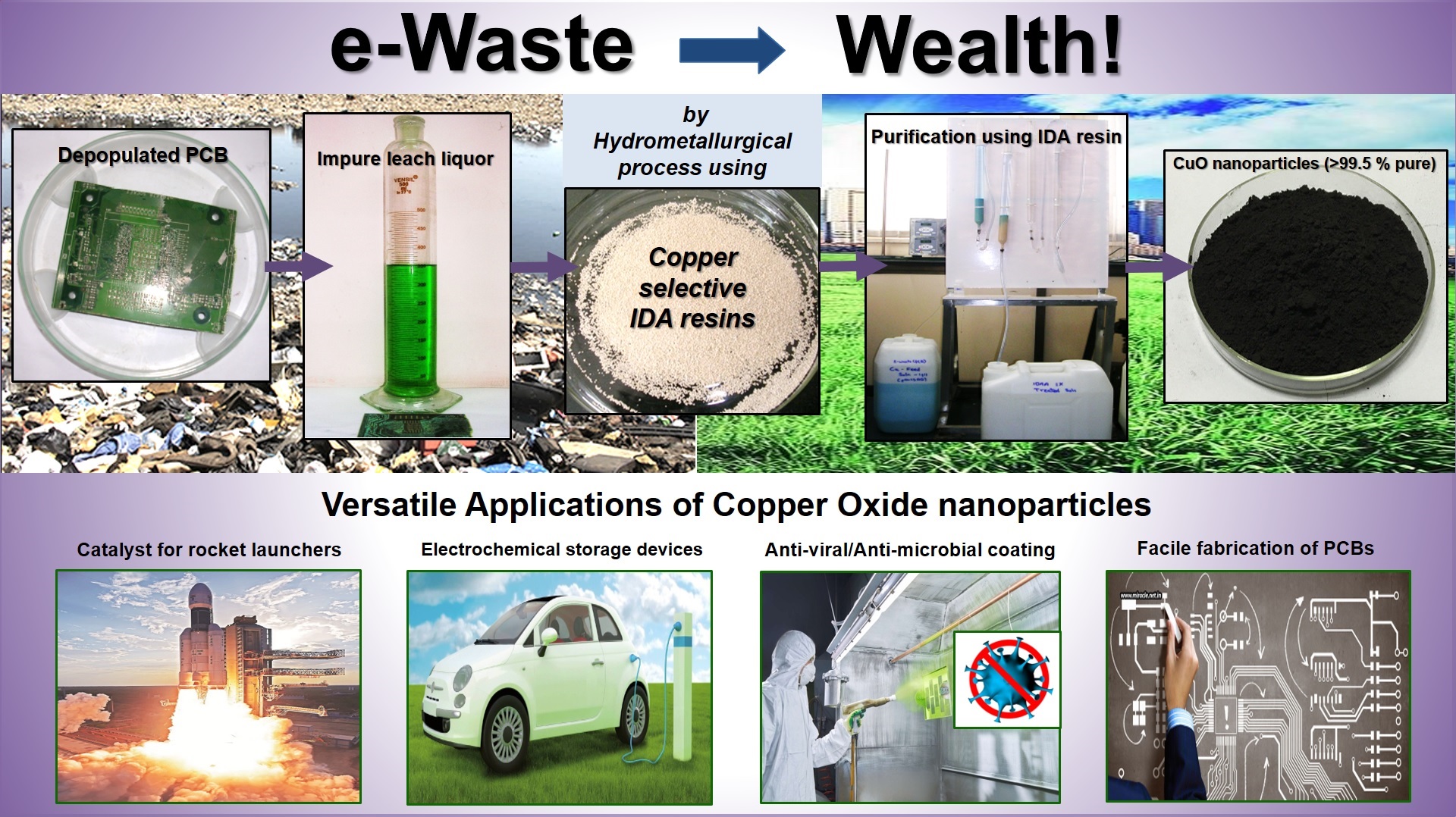

Technology involves production of high purity copper oxide nanoparticles (CuO NPs) from electronic waste via hydrometallurgical route using novel polymeric resin. The process begins with generation of acidic leach liquor of copper from printed circuit boards (PCBs), followed by feed acidity adjustment for removal of tin and selective uptake of copper using novel copper selective resin. After scrubbing under optimized conditions, high purity copper is obtained by elution with mild acid in continuous column mode. Copper is then precipitated and calcined at high temperature to yield high purity CuO nanoparticles. Further, using same resin, lead is recovered from the raffinate of leach liquor and subsequently converted into commercially valuable lead sulfide. The process therefore offers fully scalable technology for production of CuO nano particles, SnO and PbS from e-waste. This process promises abundant profit and employment opportunity to the electronic waste recycling industry, and offers long term solution to electronic waste management.

Technology involves production of high purity copper oxide nanoparticles (CuO NPs) from depopulated printed circuit boards (PCBs) via hydrometallurgical route using novel polymeric resin. The process begins with generation of acidic leach liquor of copper from printed circuit boards (PCBs), followed by feed acidity adjustment for removal of tin and selective uptake of copper using novel copper selective resin. After scrubbing under optimized conditions, high purity copper is obtained by elution with mild acid in continuous column mode. Copper is then precipitated and calcined at high temperature to yield high purity CuO nanoparticles. Further, using same resin, lead is recovered from the raffinate of leach liquor and subsequently converted into commercially valuable lead sulfide. The process therefore offers fully scalable technology for production of CuO nano particles, SnO and PbS from e-waste. This process promises abundant profit and employment opportunity to the electronic waste recycling industry, and offers long term solution for sustainable electronic waste management.

This technology empowers metal recyclers to start production of high purity copper oxide nanoparticles which has immense technocommercial applications. This process also ensures toxic 'lead' free effluent discharge from PCBs processing, hence making e-waste recycling both commercially profitable as well as enviromentally friendly.

Electronics Manufacturing, sensors and solar cells, anti-microbial and anti-fouling coatings, electrochemical energy storage, heterogeneous catalysis and rocket propulsion.

Technology involves production of high purity copper oxide nanoparticles (CuO NPs) from electronic waste via hydrometallurgical route using novel polymeric resin. The process begins with generation of acidic leach liquor of copper from printed circuit boards (PCBs), followed by feed acidity adjustment for removal of tin and selective uptake of copper using novel copper selective resin. After scrubbing under optimized conditions, high purity copper is obtained by elution with mild acid in continuous column mode. Copper is then precipitated and calcined at high temperature to yield high purity CuO nanoparticles. Further, using same resin, lead is recovered from the raffinate of leach liquor and subsequently converted into commercially valuable lead sulfide. The process therefore offers fully scalable technology for production of CuO nano particles, SnO and PbS from e-waste. This process promises abundant profit and employment opportunity to the electronic waste recycling industry, and offers long term solution to electronic waste management.

In India, according to ASSOCHAM (Associated Chambers of Commerce and Industry of India) the compound annual growth rate of e-waste is 30%, with estimated annual generation of 5.2 million tonnes of e-waste by 2020. On one hand this is a serious environmental concern due to heavy metal toxicity, on the other hand it is a promising urban mine and can become a resource of valuable metals. In recent years recycling of e-waste is considered for recovery of valuable as well as hazardous metals, one of the major components being Printed Circuit Boards (PCBs) from spent electronic accessories, which contains about 10-20% copper by mass. Although base metal copper and copper oxide (CuO) has low commercial value, CuO nanoparticles have immense commercial value and unique applications. The process developed is for specifically enabling environmentally concerned metal recyclers to achieve scaled-up production of high purity copper oxide nanoparticles in continuous mode operation from waste PCBs. The major steps are leaching, selective metal sorption/desorption by functionalized polymeric resins, precipitation and filtration of the product for final drying and packaging of CuO nanoparticles along with PbS and Sn-oxide as by-products. All the unit operations are easily scalable and the necessary process equipments are commercially available and are not capital intensive. Technology for synthesis of Cu-selective resin is also given along with the process.

This technology thus provides the advantage of commercially producing very high purity metal compounds right from e-scrap, thus providing considerable financial gains at the same time mitigating the environmental concerns of ever increasing e-waste, transforming it into a valuable resource for making the country technologically self-reliant.

This technology empowers metal recyclers to start production of high purity copper oxide nanoparticles which has immense techno-commercial value. This process also ensures toxic 'lead' free effluent discharge from PCBs processing, hence making e-waste recycling both commercially profitable as well as enviromentally friendly.

Copper oxide nanoparticles are applied in electronics Manufacturing, sensors and solar cells, anti-microbial and anti-fouling coatings, electrochemical energy storage, heterogeneous catalysis and rocket propulsion.