Phosphatic fertilizers are of great demand during recent times and the demand is increasing steadily. BARC has developed a process for development of Phosphorus fertilizer formulation from bio-sludge. Chemically synthesized phosphatic fertilizers have limitations in term of availability and they are effective at certain levels. On the contrary phosphatic fertilizer derived from biosludge are slow release and increase the crop yield at the half the recommended dose.

The process converts post biomethanation distillery sludge; a waste material for distilleries, into a high efficiency P fertilizer for soil application. The improved fertilizer helps in better phosphorus availability to the plants and also improves the crop yield and soil condition when applied to the soil.

BARC has developed a process for development of Phosphorus fertilizer formulation from bio-sludge. This will be useful for commercial preparation of advanced phosphatic fertilizer for soil application. The process converts post biomethanation distillery sludge; a waste material for distilleries, into a high efficiency P fertilizer for soil application. The improved fertilizer helps in better phosphorus availability to the plants and also improves the crop yield when applied to the soil.

PROCESS

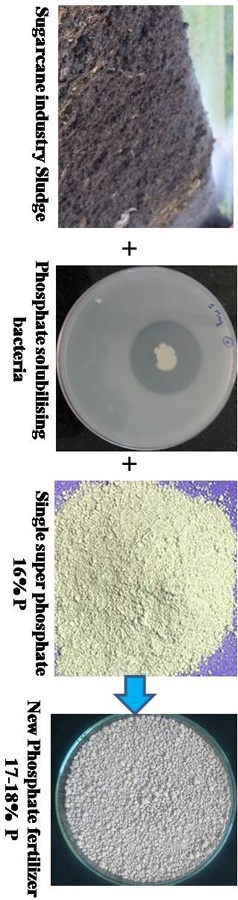

The bio-sludge from biogas generation unit of molasses based distilleries is a potential source of soluble organic matter. Using bio-sludge of molasses based distilleries, which has 21 to 23 total C and 1.0 to 1.4 % P2O5 , a high efficiency improved phosphatic fertilizer containing 17-18 % P2O5 can be developed by blending single super phosphate and phosphate solubilizing bacteria with the bio-sludge.RAW MATERIALS

INFRASTRUCTURE

MANPOWER