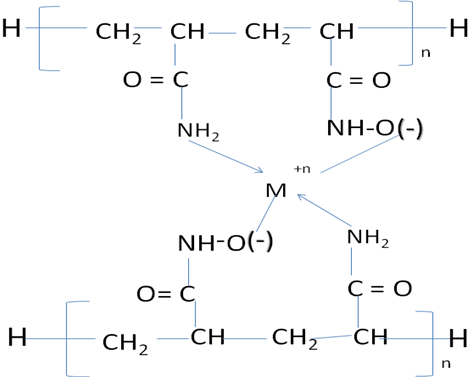

Poly-Acrylamide-Hydroxamate (PAH) is aliphatic, three dimensionally cross-linked, peach colored, irregularly shaped, highly hydrophilic weak amphoteric chromatographic resin for transition metal sequestration/chelation e.g. copper, lead, nickel, arsenic, mercury, cobalt, cadmium, molybdenum, lanthanides recovery, generated from chemical, pharmaceutical, electroplating, leather industries.

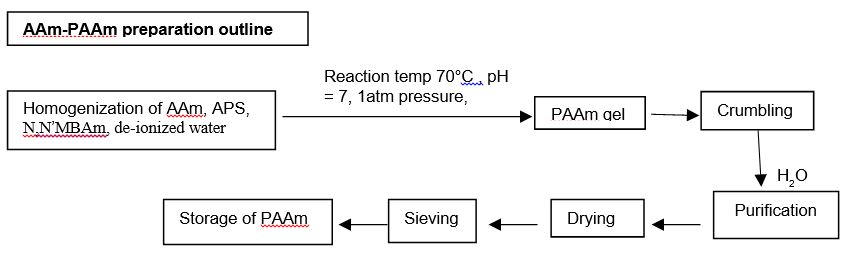

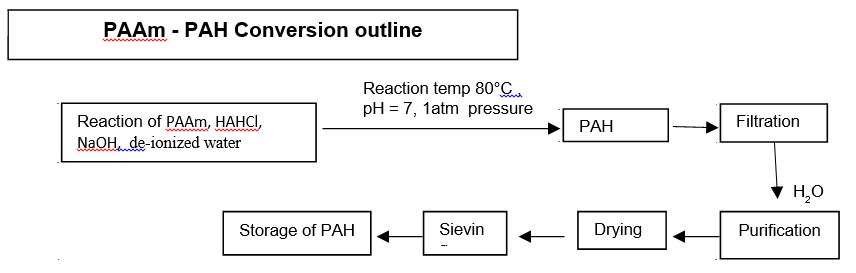

PAH is easy to synthesize, no heavy infrastructure is required, (once the reaction starts) can be left without constant monitoring and all ingredients are easily available in local market, inexpensive, water soluble and hence synthesis in aqueous (sole solvent) medium is least toxic, hazardous and with almost no volatile organic content(VOC).

PAH resin is synthesized in aqueous medium (no organic solvent) only, extremely efficient in extracting multivalent transition metal even from ppb level, reducing chemical and radio-toxicity with efficient VRF and DF helps in reducing waste inventory, risk, monitoring time and cost of managing industrial waste.

Poly-Acrylamide-Hydroxamate (PAH) is synthesized in aqueous medium (no organic solvent) only, a hydrophilic weak amphoteric chromatographic sequestration/chelation resin for copper, lead, nickel, arsenic, mercury, cobalt, molybdenum, manganese, vanadium, cadmium, lanthanides recovery. Variation in sorption kinetics and leaching of metal/s laden PAH by fractional elution are advantageous for metal ion/s as well as resin recovery with high volume reduction factor (VRF-10-100) for effluents' and metal or chemical useful for chemical, pharmaceutical, electroplating, leather industries.

Poly-Acrylamide-Hydroxamate (PAH) resin synthesis is a two-steps process; i. Polyacrylamide(PAAm) preparation, ii. Functionalization/conversion of PAAm to PAH resin. Water is the sole solvent and ingredients are water soluble. The PAH resin is useful for copper, lead, nickel, arsenic, mercury, cobalt, cadmium, lanthanides recovery, for effluents generated from chemical, pharmaceutical, electroplating, leather industries.

PAH resin has been useful in the treatment of chemical industry such as electro-deposition with expensive lanthanides recovery from effluent, laboratory effluent treatment for valuables recovery.

PAH resin is already established its features in one effluent treatment plant with three-stage-industrial effluent treatment processes and will be incorporated into future management facilities as well. As such, PAH resin will remain as an important component for effluent treatment in India in the years to come. Hence, its production and availability at a competitive price on commercial scale is of paramount importance. PAH is a solid resin with a required purity combination of 40% acrylamide and 60% hydroxamate sequestering group with cumulative structural efficacy of 98% attributed to its architectural and recurrence symmetry for efficient process operation.

Facilities required