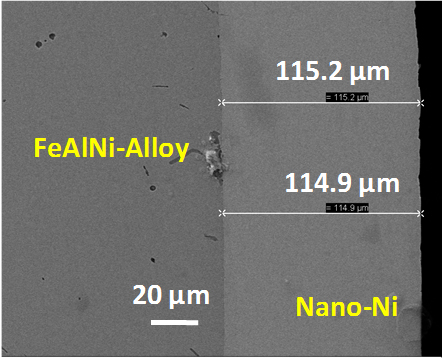

Metals and alloys containing Al, Ti, Zr and Nb are difficult-to-plate upon materials due to presence of tenacious oxide layer on their surface. These oxide layers prevent metallic bond formation between substrate and the deposited metallic coating while aqueous plating resulting into peeling/flaking off coating. However, such metals and alloys require corrosion/erosion resistant coating for variety of functional and demanding applications. The process developed here to remove such oxide layers in-situ by adopting suitable chemical/electrochemical surface engineering approach and then deposition of Nano-Ni interlayer coating. Post plating, a suitable heat-treatment was given to improve mechanical properties of the Nano-Ni coating. The Nano-Ni coating with microhardness in the range 700-900 HV100gf is highly corrosion & erosion resistant and wear resistant coating.

Metals and alloys containing Al, Ti, Zr and Nb are difficult-to-plate upon materials due to presence of tenacious oxide layer on their surface. These oxide layers prevent metallic bond formation between substrate and the deposited metallic coating while aqueous plating resulting into peeling/flaking off coating. However, such metals and alloys require corrosion/erosion resistant coating for variety of functional and demanding applications. The process developed here to remove such oxide layers in-situ by adopting suitable chemical/electrochemical surface engineering approach and then deposition of Nano-Ni interlayer coating. Post plating, a suitable heat-treatment was given to improve mechanical properties of the Nano-Ni coating.

Metals and alloys containing Al, Ti, Zr and Nb are difficult-to-plate upon materials due to presence of tenacious oxide layer on their surface. These oxide layers prevent metallic bond formation between substrate and the deposited metallic coating while aqueous plating resulting into peeling/flaking off coating. However, such metals and alloys require corrosion/erosion resistant coating for variety of functional and demanding applications. The process developed here to remove such oxide layers in-situ by adopting suitable chemical/electrochemical surface engineering approach and then deposition of Nano-Ni interlayer coating. Post plating, a suitable heat-treatment was given to improve mechanical properties of the Nano-Ni coating.

Nano-Ni coating find applications in