Mixed-matrix membrane diaphragms have been successfully used in the alkaline water electrolyser cell. The purity of the hydrogen obtained is > 99%. The cell voltage for this membrane diaphragm at a current density of 5000 A/m2 is close to the asbestos diaphragms and commercially available Zirfon membranes. It can provide an effective replacement for asbestos, and the diaphragms will be a low cost import substitute for Zirfon (~ 4 times cheaper) which can be used in production of oxygen and hydrogen in water electrolysers, chlor-alkali process, biotechnological development and batteries for space application. It is a very simple, reliable and cost effective technology for separator applications in electrochemical cells.

Mixed-matrix membrane diaphragm up to 500 mm diameter has been successfully tested in the alkaline water electrolyser cell. The purity of the hydrogen obtained is > 99 %. The cell voltage for this membrane diaphragm at a current density of 5000 A/m2 is close to the asbestos diaphragms and commercially available zirfon membranes. It can provide an effective replacement for asbestos, and the diaphragms will be a low cost import substitute for Zirfon (~ 4 times cheaper) which can be used in production of oxygen and hydrogen in water electrolysers, chlor-alkali process, biotechnological development and batteries for space application.

The diaphragms can be used as environment-friendly substitute of asbestos for separation of anodic and cathodic chambers of alkaline water electrolysis cell for production of oxygen and hydrogen in water electrolyzers, chlor-alkali process, biotechnological development and batteries for space application.

The mixed-matrix membrane diaphragm is a very simple, reliable and cost effective product for separating the alkaline water electrolysis chambers (anode and cathode). The high leaching rate of asbestos at high temperature in strong alkaline environment limits the desirable efficiency of the electrolyzer at higher temperature. More recently, due to its seriously adverse health effect, replacements are being actively sought after. This diaphragm can provide an effective replacement for asbestos and the diaphragms will be a low cost import substitute for Zirfon (~ 4 times cheaper), which can be used in production of oxygen and hydrogen in water electrolyzers, chlor-alkali process, biotechnological development and batteries for space application.

Mixed-matrix membrane diaphragm up to 500 mm diameter has been successfully tested in the alkaline water electrolyser cell. The purity of the hydrogen obtained is > 99 %. The cell voltage for this membrane diaphragm at a current density of 5000 A/m2 is close to the asbestos diaphragms and commercially available Zirfon membranes. It can provide an effective replacement for asbestos, and the diaphragms will be a low cost import substitute for Zirfon (~ 4 times cheaper) which can be used in production of oxygen and hydrogen in water electrolysers, chlor-alkali process, biotechnological development and batteries for space application.

The diaphragms can be used as environment-friendly substitute of asbestos for separation of anodic and cathodic chambers of alkaline water electrolysis cell for production of oxygen and hydrogen in water electrolyzers, chlor-alkali process, biotechnological development and batteries for space application.

The mixed-matrix membrane diaphragm is a very simple, reliable and cost effective product for separating the alkaline water electrolysis chambers (anode and cathode). The high leaching rate of asbestos at high temperature in strong alkaline environment limits the desirable efficiency of the electrolyzer at higher temperature. More recently, due to its seriously adverse health effect, replacements are being actively sought after. The diaphragm can provide an effective replacement for asbestos and the diaphragms will be a low cost import substitute for Zirfon (~ 4 times cheaper) which can be used in production of oxygen and hydrogen in water electrolyzers, chlor-alkali process, biotechnological development and batteries for space application.

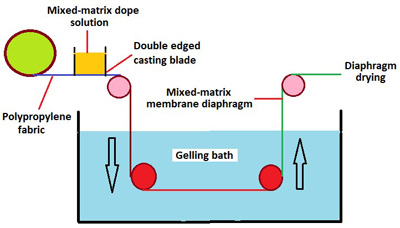

The process involves preparation of polysulfone-zirconia (ZrO2) mixed-matrix membrane dope solution and its casting on a polypropylene fabric, using a membrane casting machine. It involves simple chemicals available in the local market. The machine assemblies can also be fabricated with standard materials and mechanical/ electronic components. The present product can replace the carcinogenic asbestos currently being used in electrolyzers. Also, it will be a suitable alternative of imported Zirfon diaphragm.

It requires below mentioned machine and rooms with controlled temperature (23 ± 2 °C) and relative humidity (< 40 %):