DNA micro array technology is a powerful tool emerging in the field of functional genomics. The DNA Microarrayer is a very precise computer controlled 3-axis robotics system for making DNA microarrays to find out the expression levels of large number of genes simultaneously and genetic disorder in clinical diagnostic. The most challenging task is to print large number of DNA samples of all sequences at a very small area in few nano-litres quantities with micron level positional accuracy. The design of precise robotic system and its software for automation of the process has helped in achieving and maintaining desired level of accuracy needed for the system along with user friendly features.

The Microarrayer is a very precise computer controlled 3-axes robotics system to deposit high-density, gridded arrays of genomic DNA or similar biological materials at discrete locations in microscopic quantities. Such a capability permits for all possible genes that can be expressed in a given organism in a two-dimensional array at a high-density on a solid surface for high throughput analysis. These targets are then hybridized with fluorescence labeled complimentary sequences in a test sample (DNA or RNA). It is the first indigenously developed system in BARC and promises to make mutation detection, gene expression analysis and disease diagnosis in less time and is more efficient, thus revolutionizing in area of biotechnology and medicine.

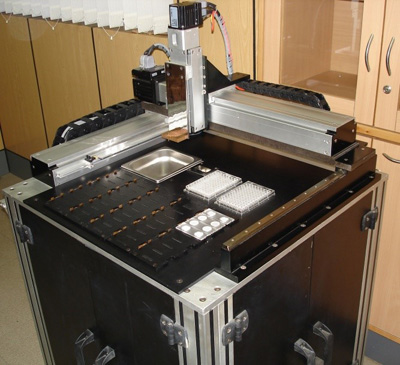

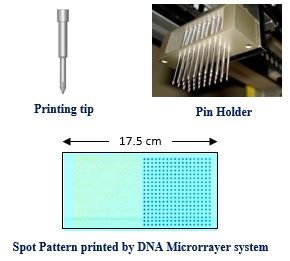

The Microarrayer is a very precise computer controlled 3-axes robotics system to deposit high-density, gridded arrays of genomic DNA or similar biological materials at discrete locations in microscopic quantities. The robotic system based on servo motors with high-resolution encoders & advanced control scheme, well damped table and unique pin tip assembly to provide better positional accuracy of few micron, higher throughput and user friendly control software to define all critical parameters for printing operation. Both hardware and software are designed to provide high performance automation together with the flexibility required for individual sample handling and custom designed. The robot is designed to collect samples automatically from the wells of either a 96 or a 384-well micro-titre plate with up to 32 specially made pins by capillary action and deposits approximately 1 nano-litre on each slide.

SPECIFICATIONS

| Positional repeatability | 10 micron |

|---|---|

| Liquid handling / delivery (Capillary) | ~1 nano-litre – 1 pico-litre per spot |

| Printing density | 7000 per slide |

| Printing type | Contact printing |

| Slide handling capacity | Up to 40 slides |

| Spot Diameter | < 300 microns |

| Dimensions | 72 x 70 x 120 cm (W x D x H) |

| Weight | 70 kg |

| Maximum Well Plates | 2 |

| Pin Holder capacity | 32 Pins |

SPACE

MANPOWER

POWER

TEST EQUIPMENTS

OTHER FACILITIES