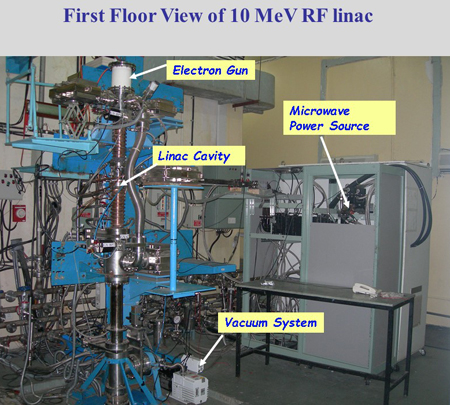

Electron beams have played a key role in the field of basic and applied sciences. Over the last decade or so, the focus has mainly shifted to industrial applications, where the electron beams are being employed for various uses. 10 MeV, 5 kW electron beams are found highly suitable for food irradiation, medical sterilization, cross linking of cables, radiographic applications, semiconductor and diamond irradiation industries. The field is growing and expanding at a fast pace with more and more avenues opening up daily. Electrons from the electron gun are injected into the RF linac at an energy of 40-60 keV. These electrons are then accelerated through the linac, up to a beam energy of 10 MeV. After acceleration, the magnetic sweep scanner deflects the beam in the scan horn and taken out in the atmosphere through a 100 cm X 7 cm, 50-micron thick titanium foil window for radiation processing applications.

Prototype demonstration will be done at 3kW for continuous operation.

Electron beams have played a key role in the field of basic and applied sciences. Over the last decade or so, the focus has mainly shifted to industrial applications, where the electron beams are being employed for various uses. 10 MeV, 5 kW electron beams are found highly suitable for food irradiation, medical sterilization, cross linking of cables, radiographic applications, semiconductor and diamond irradiation industries. The field is growing and expanding at a fast pace with more and more avenues opening up daily. Keeping in mind the enormous potential of electron beams and to exploit their industrial uses, BARC/APPD has taken up an elaborate programme for designing and building the 10 MeV electron accelerator. It is housed at Electron Beam Center (EBC), situated at Kharghar, Navi Mumbai. Electrons from the electron gun are injected into the RF linac at an energy of 40-60 keV. These electrons are then accelerated through the linac, up to a beam energy of 10 MeV. After acceleration, the magnetic sweep scanner deflects the beam in the scan horn and taken out in the atmosphere through a 100 cm X 7 cm, 50-micron thick titanium foil window for radiation processing applications.

Specification of 10 MeV LINAC

| Sr. No. | Parameters | Value |

|---|---|---|

| 1 | Beam Energy (MeV) | 10.0 ± 0.1 |

| 2 | Beam Current (mA) | 0.5 |

| 3 | Average Beam Power (kW) | 1- 5 (max) |

| 4 | Operating Frequency range (MHz) | 2856 ± 2 MHz |

| 5 | Beam Pulse Width (µsec) | 10.0 |

| 6 | Pulse repetition rate (Hz) | 50-250 (max) |

| 7 | Injection Voltage (kV) | 40-50 (max) |

| 8 | Length of system (m) | 4-5 |

| 9 | Cooling LCW Water Temperature | 22-25 °C |

| 10 | Length of LINAC structure (m) | 0.9 |

Electron beams have played a key role in the field of basic and applied sciences. Over the last decade or so, the focus has mainly shifted to industrial applications, where the electron beams are being employed for various uses. 10 MeV, 5 kW electron beams are found highly suitable for food irradiation, medical sterilization, cross linking of cables, radiographic applications, semiconductor and diamond irradiation industries. The field is growing and expanding at a fast pace with more and more avenues opening up daily. Keeping in mind the enormous potential of electron beams and to exploit their industrial uses, BARC/APPD has taken up an elaborate programme for designing and building the 10 MeV electron accelerator. Electrons from the electron gun are injected into the RF linac at an energy of 40-60 keV. These electrons are then accelerated through the linac, up to a beam energy of 10 MeV. After acceleration, the magnetic sweep scanner deflects the beam in the scan horn and taken out in the atmosphere through a 100 cm X 7 cm, 50-micron thick titanium foil window for radiation processing applications.

Specification of 10 MeV LINAC

| Sr. No. | Parameters | Value |

|---|---|---|

| 1 | Beam Energy (MeV) | 10.0 ± 0.1 |

| 2 | Beam Current (mA) | 0.5 |

| 3 | Average Beam Power (kW) | 1- 5 (max) |

| 4 | Operating Frequency range (MHz) | 2856 ± 2 MHz |

| 5 | Beam Pulse Width (µsec) | 10.0 |

| 6 | Pulse repetition rate (Hz) | 50-250 (max) |

| 7 | Injection Voltage (kV) | 40-50 (max) |

| 8 | Length of system (m) | 4-5 |

| 9 | Cooling LCW Water Temperature | 22-25 °C |

| 10 | Length of LINAC structure (m) | 0.9 |