This is most suitable to detect trace levels (<1ppm) of hydrogen sulfide at room temperature.

Hydrogen sulfide is a toxic and flammable gas, usually generated in sewages, swamps, mines etc, which necessitates the detection of the gas in sub ppm level as it reacts strongly with living tissues and attacks the central nervous system. Higher concentration or prolonged exposure of H2S paralyses the olfactory system. We have exploited surface conductivity of hydrogen terminated diamond films to detect trace levels (<1ppm) of hydrogen sulfide at room temperature.

Hydrogen sulfide is a toxic and flammable gas, usually generated in sewages, swamps, mines etc. Hydrogen sulfide gas detector finds application in petroleum refineries, paper mills, tanneries and other industries, laboratories, and in heavy water plants where it is used as a process gas. It is imperative that the gas should be detected in ppm levels in air by selective and sensitive sensors. We have exploited surface conductivity of hydrogen terminated diamond films to detect trace levels (<1ppm) of hydrogen sulfide at room temperature.

Hydrogen sulfide is a toxic and flammable gas, usually generated in sewages, swamps, mines etc. Hydrogen sulfide gas detector finds application in petroleum refineries, paper mills, tanneries and other industries, laboratories, and in heavy water plants where it is used as a process gas. Hydrogen sulfide reacts strongly with living tissues and attacks the central nervous system. Human nose is sensitive to trace amount (0.2 ppm) of H2S, which is recognized by a distinctive odor of rotten eggs. Higher concentration or prolonged exposure of H2S paralyses the olfactory system. Thus it is imperative that the gas must be detected in ppm levels in air by selective and sensitive sensors.

Diamond is a unique material with a wide range of mechanical, optical, electrical, thermal and chemical properties. Though undoped diamond is an excellent insulator, hydrogen terminated diamond shows p-type surface conductivity, which has been exploited to detect trace levels (<1ppm) of hydrogen sulfide at room temperature.

Raw Materials

Equipments

Equipment no. 4, 5 and 6 are not necessary if dicing, bonding and packaging can be outsourced.

Space requirements

Man power

A highly sensitive and selective H2S sensor with monitor (Model: TPD-BARC 1050) suitable for detection in 10-50 parts-per-million (ppm) range.

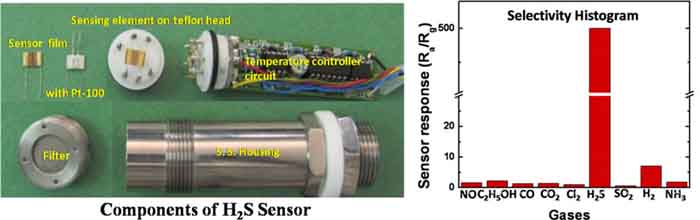

A highly sensitive and selective H2S sensor with monitor (Model: TPD-BARC 1050) suitable for detection in 10-50 parts-per-million (ppm) range is developed. The sensor exhibits a response (Rair/Rgas) of ~ 500 (@ 50 ppm of H2S) and is selective to H2S with a meagre response (i.e. < 10) towards other interfering gases like NO, C2H5OH, CO, CO2, Cl2, SO2, H2 and NH3. The sensor is coupled to a digital monitor that directly displays the H2S concentration in ppm. The monitor has provisions for programmable alarm set points.

H2S is widely used either as a process gas or it is a byproduct in laboratories and different industries e.g. heavy water plants, oil and gas industries, pulp and paper industries, sewage treatment plants and chemical industries. H2S is highly toxic and flammable gas and its exposure in high doses can affect the human’s nervous system. H2S has long-term (8 h) and short-term (10 minutes) exposure limits of respectively, 10 and 15 ppm, which demand continuous monitoring of H2S in laboratories and industries. For this purpose, BARC has developed a H2S Sensor with Monitor (Model: TPD-BARC 1050), which can monitor the gas in 10-50 ppm range.

The H2S Sensor with Monitor (Model: TPD-BARC 1050) is a chemiresistive type and works on the principle of change in electrical resistance upon a chemical interaction with H2S. This change is calibrated and displayed directly on a digital monitor as H2S concentration in ppm

H2S is one of the highly toxic and flammable gases, which is widely used in various industrial applications. Its long-term (8 h) and short-term (10 minutes) exposure limits are respectively, 10 and 15 ppm. The H2S Sensor with Monitor (Model: TPD-BARC 1050) detects H2S using a chemiresistive element, which is highly sensitive, selective to H2S, and stable for more than 2 years. It comprises of a "Sensor Head" and a "Digital Monitor".

Sensor Head

The sensor head consists of a sensing element, heater and temperature controller circuit encased in stainless steel housing. The active element is SnO2:CuO thin film mounted on a heater. The best response for H2S gas is obtained in the temperature range of 170 -190°C.

Digital Monitor

It consists of a Data Acquisition & Control Board, and touch screen based Human-machine interface (HMI) module. The sensor output i.e. the change in resistance as a function of concentration, is provided to the monitor capable of displaying the gas concentration in ppm. The monitor has provision for programmable alarm set points, touch switch to change between Normal and Calibration Mode and store Historical Logs (installation date, calibration date, fault detail etc). Default alarms have been set at 10 and 50 ppm.

The sensor works on the principle of change in electrical resistance upon a chemical interaction with H2S. This change is calibrated and displayed directly on a digital monitor as H2S concentration in ppm.

The sensor element is a SnO2: CuO thin film, in which the p-type CuO and n-type SnO2 form random p-n junctions, leading to a very high resistance in air (of the order of MΩ). On H2S exposure, CuO converts to metallic CuS which results in a drastic decrease in electrical resistance. In the presence of air, CuS gets converted back to CuO and the original state is restored. As both the chemical reactions are unique to H2S, therefore these sensors exhibit negligible response towards other gases.

| Sr. No. | Specification | Value |

|---|---|---|

| 1 | H2S detection range | 10 - 50 ppm |

| 2 | Operating temperature | 170 -190°C. |

| 3 | Response time (time to reach 90% of the resistance change) | 3 - 5 min. |

| 4 | Recovery time (time to reach 10% of the resistance change) | < 15 min. |

| 5 | Response at 50 ppm H2S (Rair/Rgas) | > 500 |

| 6 | Selectivity for H2S (comparison to NO, CO2, Cl2, SO2, H2, NH3 etc.) (Response (Rair/Rgas) of sensor towards H2S is ~500 as compared to its response towards other gases. Please refer graph) |

Excellent |

| 7 | Life time under operating conditions | ~ 2 years |

Sensor head

Digital monitor

Sensor calibration

Space

2 Numbers