The instrument is primarily useful for the vacuum leak testing of UHV components, chambers, enclosures, vacuum sealings, large experimental facilities etc.

The instrument is primarily useful for the vacuum leak testing of UHV components, chambers, enclosures, vacuum sealings, large experimental facilities etc. The basic principle involves three different components viz., an ionization source along with suitable ion-optics, mass analyzer and ion detector- all supported by suitable electronics and vacuum. The job under investigation for leak is connected with the leak detector. Helium is sprayed on the suspected parts and enters through the leak into the detector spectrometer. The helium ions are generated by electron impact which are accelerated, focused and deflected by a magnet analyser to the Faraday collector. The ion current so collected is measured and calibrated to indicate the leak rate of Helium to establish the presence and also level of the leak. It is a highly reliable and widely used method for leak testing applications.

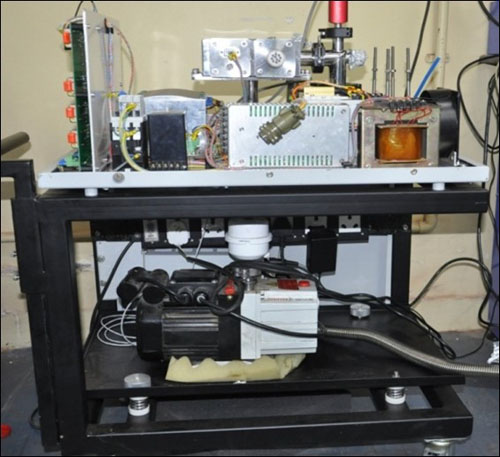

GENERAL

| Dimension | 700 mm (L) x 500 mm (W) x 1000 (H) |

|---|---|

| Dimension | 700 mm (L) x 500 mm (W) x 1000 (H) |

| Test Connection | 25 ISO KF |

| Main Voltage | 220 V |

| Mains Frequency | 50 Hz |

| Mains Current | < 10 A |

| Power | < 1 kW |

Ion Source

| Type | Electron bombardment |

|---|---|

| Filament | Tungsten Wire (5 mil diameter) |

| Accelerating Potential | 450 volt |

| Geometry | Nier Type |

| Electron beam focusing | by permanent magnet (Field : ~ 100 gauss) |

Analyser

| Type | Permanent Magnet (Ferrite) |

|---|---|

| Geometry | Normal |

| Bending Angle | 180 deg |

| Radius | 5 cm |

| Magnetic Field | 1500 gauss |

Collector

| Type | Faraday |

|---|---|

| Opening Size | 3mm width x 10 mm height |

| Measurement system | Electrometer amplifier |

| Gain Resistance/th> | 1 x 10(12) ohm< |

| Time constant | 1 sec |

Vacuum system

| Vacuum pump (MS) | TMP with pumping speed 30 L/s |

|---|---|

| Vacuum pump (backing) | Rotary pump (Pumping speed: 5 m3/h) |

| Valve manifold | Aluminium make with 7 ports |

| Valve type | Electromagnetic |

| Valve leak tightness | < 1x 10(-8) torr L/s |

| Modes | Counter flow, Main flow, sniffer |

Software

| Operation | Auto start/stop, leak measurement |

|---|---|

| Mode selection | Semi automatic |

RAW MATERIAL

INFRASTRUCTURE REQUIRED

Electronic Lab Facility for Testing Purpose