Large quantities of oily waste (i.e. water containing dissolved oil) are generated due to industrial operation. More often than not such waste water is associated with dissolved salts. One example is produce water which is generated during oil drilling operations. For land locked oil platforms the separated water is typically re injected into the well as it is not suitable for surface discharge. This becomes an expensive affair and also represents lost opportunity for gain full utilization of a large quantity of water. This technology will ensure such dissolved oil and salt containing water can be treated efficiently so that they can be discharged on surface. More over this water will be useful for agriculture/process industry/surface water recharge and such other gain full applications and will be of significant value in arid/rain deficient regions.

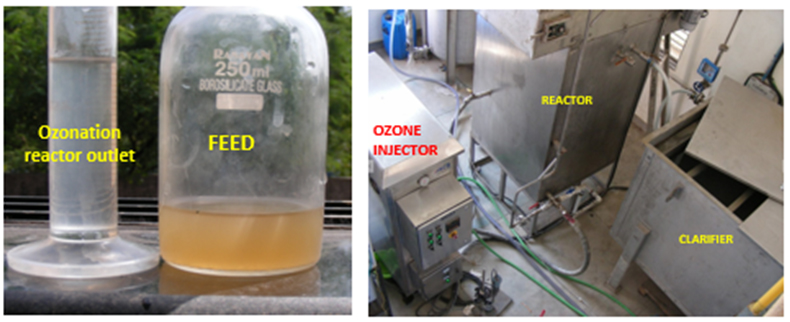

Large quantities of waste water having dissolved oil and salt is typically produced due to industrial operation. One such example is produce water that is generated during oil drilling operations. For land locked oil platforms the separated water is typically reinjected into the well (a costly affair) as it is not suitable for surface discharge. In our process we use micro-nano bubbles of in-situ generated ozone gas to oxidize and remove dissolved oil from waste water. Dissolved salt removal is achieved using a Reverse Osmosis step in the tail end. The final water is thus free of dissolved oil and salt and can be discharged on surface. In parlance of produce water this technology will reduce reinjection cost. This water is also suitable for agricultural use and/or other gain full applications (industry process water, water reuse etc.). Such usages become all the more important if the industry is located in rain deficient/arid regions.

Large quantities of waste water having dissolved oil and salt is typically produced due to industrial operation. One such example is produce water that is generated during oil drilling operations. For land locked oil platforms the separated water is typically reinjected into the well (a costly affair) as it is not suitable for surface discharge. In our process we use micro-nano bubbles of in-situ generated ozone gas to oxidize and remove dissolved oil from waste water. Dissolved salt removal is achieved using a Reverse Osmosis step in the tail end. The final water is thus free of dissolved oil and salt and can be discharged on surface. In parlance of produce water this technology will reduce reinjection cost. This water is also suitable for agricultural use and/or other gain full applications (industry process water, water reuse etc.). Such usages become all the more important if the industry is located in rain deficient/arid regions.