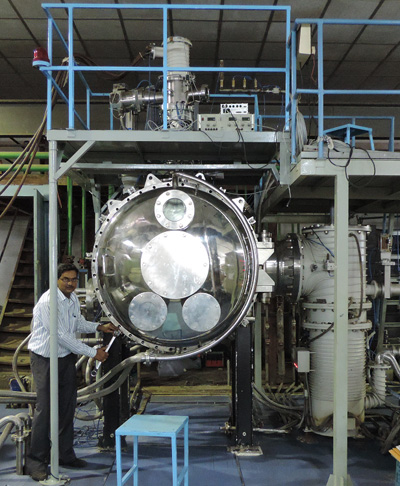

Electron beam melting (EBM) process uses heat obtained from the impingement of high energy intense electron beam for vacuum melting, scrap consolidation and metallurgical refining of reactive, refractory and special alloys. Electrons generated by thermionic emission are accelerated and focused with the help of electric and magnetic fields in high vacuum to the target to be melted. Electron beam melting gun column comprises of generation, acceleration, focusing and maneuvering of high intensity electron beam. The technology and knowhow of a 35kV, 100kW EBM Gun Column developed at Bhabha Atomic Research Centre is available for transfer to industry. EB Melting Gun column and its power source can be integrated to a process chamber designed as per user specification to make EB Machines for the drip melting and Hearth Melting of reactive, refractory and special alloys (such as Nb, Ti, Nb-Ti, Zr alloys etc.).

Electron beam melting (EBM) process uses heat obtained from the impingement of high energy intense electron beam for vacuum melting, scrap consolidation and metallurgical refining of reactive, refractory and special alloys. Electrons generated by thermionic emission are accelerated and focused with the help of electric and magnetic fields in high vacuum to the target to be melted. Electron beam melting gun column comprises of generation, acceleration, focusing and maneuvering of high intensity electron beam. The technology and knowhow of a 35kV, 100kW EBM Gun Column developed at Bhabha Atomic Research Centre is available for transfer to industry. EB Melting Gun column and its power source can be integrated to a process chamber designed as per user specification to make EB Machines for the drip melting and Hearth Melting of reactive, refractory and special alloys (such as Nb, Ti, Nb-Ti, Zr alloys etc.).

Electron beam melting (EBM) process uses heat obtained from the impingement of high energy intense electron beam for vacuum melting, scrap consolidation and metallurgical refining of reactive, refractory and special alloys. Electrons generated by thermionic emission are accelerated and focused with the help of electric and magnetic fields in high vacuum to the target to be melted. Electron beam melting gun column comprises of generation, acceleration, focusing and maneuvering of high intensity electron beam. The technology and knowhow of a 35kV, 100kW EBM Gun Column developed at Bhabha Atomic Research Centre is available for transfer to industry. EB Melting Gun column and its power source can be integrated to a process chamber designed as per user specification to make EB Machines for the drip melting and Hearth Melting of reactive, refractory and special alloys (such as Nb, Ti, Nb-Ti, Zr alloys etc.).

The major advantage of EB Melting is that the melting and consolidation is carried out in vacuum environment and therefore most suitable for refining of reactive and refractory metals and alloys.

Indigenous manufactured machines costing nearly a third of the imported machines and could prove a cost effective solution to help the domestic industry to improve product quality.