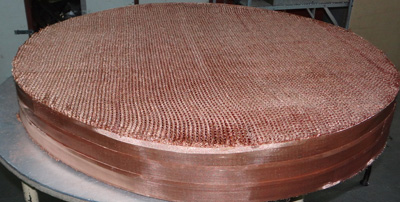

Distillation columns are used extensively in the chemical process industries for separating a variety of fluid mixtures. These indigenously developed high efficiency structured packing filled distillation columns are used for separating mixtures in which the components have very close boiling points and hence low separation factors.

Distillation columns are used extensively in the chemical process industries for separating a variety of fluid mixtures. These indigenously developed high efficiency structured packing filled distillation columns are used for separating mixtures in which the components have very close boiling points and hence low separation factors.

Indigenous development of structured packing and column sections is cost effective, eliminates the need for depending on imported proprietary items from foreign suppliers (which are generally not even available to certain sectors like the nuclear industry on account of existing embargos) and conforms to the “Make in India” philosophy as well. It has huge market potential to cater to the future projects of NPCIL regarding PHWR based nuclear power plants.

This distillation column fabrication technology has applications in areas of heavy water production from light water by vacuum distillation and in upgrading of heavy water for the nuclear industry; also useful for other difficult separation operations in the general chemical process industries.

EQUIPMENTS

INFRASTRUCTURE

MANPOWER

The manpower required for fabricating and testing this system should have expertise in structured packing fabrication including operations like pneumatic grinding, cutting, punching, welding, precision machining and assembly of the units.