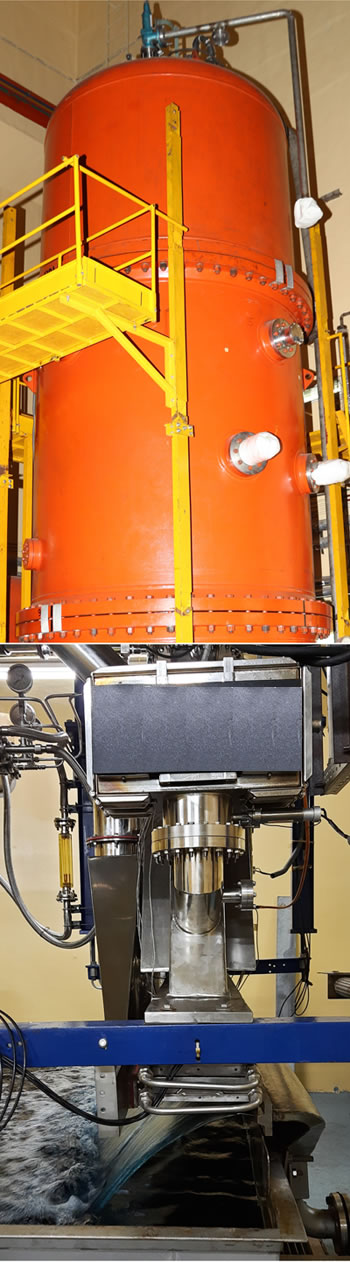

A high power DC accelerator has high throughput for radiation processing applications viz waste water treatment, cable irradiation, modification of plastics, cross-linking & grafting, pollution control, etc. Energy for electron acceleration is provided by an efficient high voltage multiplier which is housed in a pressure vessel in N2-SF6 gas mixture environment at 6.0 kg/cm2 pressure. Electron beam is generated by thermionic electron gun and accelerated in high vacuum in accelerating tubes. The accelerated beam is transported, steered, focused and scanned and is extracted in atmosphere through a titanium foil window. The extracted beam falls on product for various industrial radiation processing applications.

Prototype demonstration will be done at 0.8-1.0MeV beam energy, 0-50mA beam current and 40kWmax beam power for continuous operation.

A high power DC accelerator has high throughput for radiation processing applications viz waste water treatment, cable irradiation, modification of plastics, cross-linking & grafting, pollution control, etc. Energy for electron acceleration is provided by an efficient high voltage multiplier which is housed in a pressure vessel in mixture of N2-SF6 gas environment at 6.0 kg/cm2 pressure. Electron beam is generated by thermionic electron gun and accelerated in high vacuum in accelerating tubes. The accelerated beam is transported, steered, focused and scanned and is extracted in atmosphere through a titanium foil window. The extracted beam falls on product for various industrial radiation processing applications.

This is ON/ OFF technology, i.e. when Machine is switched off, there is no radiation. Therefore, maintenance is in conventional manner and no there is no issues related to security and radioactive waste handling, transportation, disposal as in Cobalt-60. Also, the energy and intensity remain constant during operation of accelerator. There is no consumption of electric power when machine is shut off, except the utilities like lighting. The technology is environment friendly and user friendly.

| DC Accelerator Parameters | |

|---|---|

| Beam Energy | 0.8 -1.0 MeV±10 % |

| Beam Power | 0 - 100 kW max |

| Accelerator Type | DC Electron beam continuous (Cockcroft Walton Type) |

| HF Input source | 10kHz IGBT Based Inverter |

| Electron Source | Thermionic ally Heated LaB6 Cathode |

| Accelerating Column | 6 Nos of 335kV rated tube |

| Beam Line Length | 1.9m with beam optics (Steering, Focusing& Scanning) |

| Accelerator Tank Dimension | 1.6m (ID) and 3.6m height |

| Electron Beam window | 1500mm×100mm |

| Dose | 1700kGy/min |

This machine can be considered as the workhorse for industrial radiation processing applications like modification of bulk polymers, cross linking of cables, degradation of scrap Teflon and cellulose materials, diamond colouring, small scale industrial flue gas treatment and waste water treatment.

A high power DC accelerator has high throughput for radiation processing applications viz waste water treatment, cable irradiation, modification of plastics, cross-linking & grafting, pollution control, etc. Electron Beam Centre, BTDG, BARC has developed a DC electron beam accelerator in the energy range of 1-3MeV and beam current range of 0-100mA and demonstrated for Electron Beam Waste Water Treatment (EBWWT) using simulated test facilities. Energy for electron acceleration is provided by an efficient high voltage multiplier which is housed in a pressure vessel in N2-SF6 gas mixture environment at 6.0 kg/cm2 pressure. Electron beam is generated by thermionic electron gun and accelerated in high vacuum in accelerating tubes. The accelerated beam is transported, steered, focused and scanned and is extracted in atmosphere through a titanium foil window. The extracted beam falls on product for various industrial radiation processing applications .The accelerator and its sub-systems have been designed, keeping in mind safe and secure operation for the machine, as well as human safety. All systems have their individual interlocks and the control systems ensure that, in case of failure of any sub-system, the machine is shut down in a safe manner and no risk to personnel health is involved.

| DC Accelerator Parameters | |

|---|---|

| Beam Energy | 0.8 -1.0 MeV±10 % |

| Beam Power | 0 - 100 kW max |

| Accelerator Type | DC Electron beam continuous (Cockcroft Walton Type) |

| HF Input source | 10kHz IGBT Based Inverter |

| Electron Source | Thermionic ally Heated LaB6 Cathode |

| Accelerating Column | 6 Nos of 335kV rated tube |

| Beam Line Length | 1.9m with beam optics (Steering, Focusing& Scanning) |

| Accelerator Tank Dimension | 1.6m (ID) and 3.6m height |

| Electron Beam window | 1500mm×100mm |

| Dose | 1700kGy/min |