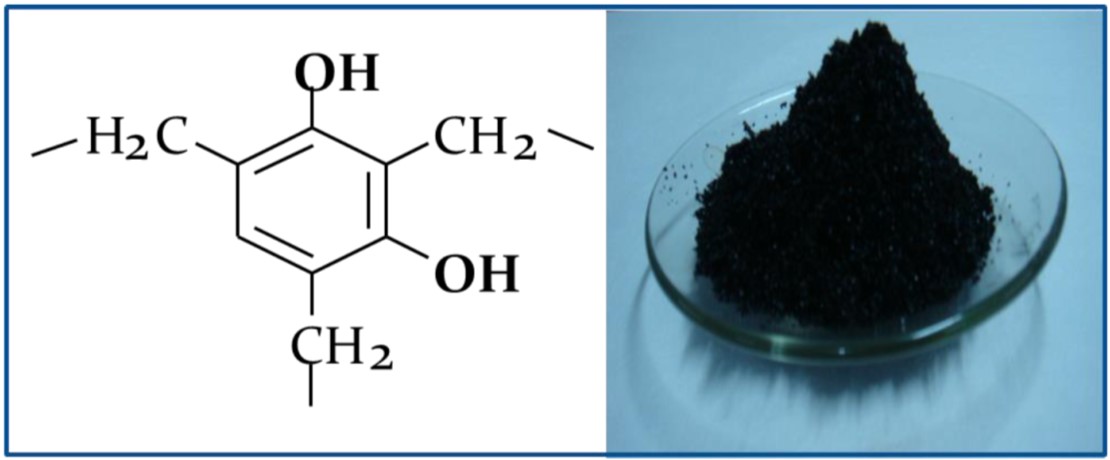

RFPR is a polymeric resin synthesized vides alkali catalyzed polycondensation reaction of resorcinol and formaldehyde. The polymeric gel after curing in air oven followed by crushing and sieving gives the dark brown granular product.

BARC has developed full scale technology for the bulk production of the resin. The resin produced under optimum conditions picks up traces of Cesium isotopes very selectively from alkaline solutions containing molar level of competing sodium ions. The process for the synthesis and its applications is well established in industrial scale. It is the work-horse in the area of Cesium separation. DAE has three industrial scale facilities, which are in operations over the decades.

Parties with sound financial background, bulk chemical manufacturing facilities, R&D labs for quality assessment, and having experience in developing such specialty chemicals will be preferred.

RFPR is a unique specialty chemical used in the treatment of nuclear waste to reduce its long-term radio-toxicity. The resin specifically separates cesium from alkaline intermediate level waste and has been tested in plant scale in waste management facilities in India. The procedures for the synthesis, conditioning and quality analysis of this resin have been developed and standardized. To ensure the commercial availability of this resin with cost effectiveness, there is a need to develop vendors for its bulk production and regular supply to ensure sustained plant operations.

Resorcinol-Formaldehyde Polycondensate Resin (RFPR) is deployed for selective separation of Cesium from alkaline intermediate level waste in Waste Management Facilities/Plants across DAE units. This process employing RFPR is a well tested in plant scale and has become an integral part in waste management practices in India. The procedures for the synthesis, conditioning and quality analysis of this resin have been developed and standardized. As such, this resin will remain as an important ion-exchange material for nuclear waste management in India in the years to come. Hence, its production and availability at a competitive price on commercial scale is of paramount importance. RFPR is a dark brown red solid with a required cation exchange capacity (H+ to Na+) of around 6 meq/g.

a. Facilities required

b. Manpower Requirement

c. Raw material Requirement