Petroleum based packaging materials are threat to environment due to their non-biodegradability and non-renewability. Hence Government of India has banned the use of plastics. Biopolymers based films could provide suitable alternatives for these petroleum based products. Bhabha Atomic Research Centre in Collaboration with Central Institute of Petrochemicals and Engineering Technology (CIPET): Laboratory for Advanced Research in Polymeric Materials (LARPM), Bhubaneswar has developed Biodegradable Films using Guar Gum, a widely available Biopolymer and Poly Vinyl Alcohol (PVA) which can be easily scale up industrially. It is an intelligent technological advancement for the economical & environmental solution for the plastics packaging films. It has a comparable mechanical and barrier properties with commercially available stretch wrap films and no specific environment is required for its degradation.

Bhabha Atomic Research Centre in collaboration with Central Institute of Petrochemicals and Engineering Technology (CIPET): Laboratory for Advanced Research in Polymeric Materials (LARPM), Bhubaneswar has developed biodegradable films using guar gum, a widely available biopolymer and poly vinyl alcohol (PVA). It is an intelligent technological advancement for the economical & environmental solution for the plastics packaging films. Biodegradable films are alternative to commercial petroleum based films.

The electron gun can also be used for various extraction voltage and corresponding beam current extractions and can also be easily operated in Triode mode with a grid bias.

INTRODUCTION

In the past twenty years, the production and use of plastics in the world has increased enormously to about 295 million metric tons per year. Packaging constitutes the largest market for plastics, amounting to over 34 percent of total plastics produced. Increasing demand for synthetic packaging materials has put tremendous pressure on the environment because of their poor biodegradability and non-renewability. This has led to a search for packaging materials that are biodegradable as well as recyclable. One of the alternatives is the development of packaging material from biopolymers (i.e. protein, polysaccharide and lipid) that are biodegradable, non-toxic and derived from completely renewable resources. Among the biopolymers, polysaccharides are the most widely used for preparation of packaging films.

Most widely studied polysaccharides biodegradable films are: starch, chitosan, carrageenan, and galactomannans. However, there are several limitations in the use of biopolymers as packaging materials such as their relatively poor mechanical strength and lower barrier to water and gases like CO2 and O2 as compared to their non-biodegradable counterparts. This has resulted in a greater focus on improving the properties of these polymers to match the commercially available packaging material. Various methods including addition of plasticizer, chemical modifications, gamma radiation and use of different additives for improving properties of natural biopolymer based films are reported in literature. However, generally in literature preparation of biodegradable films are detailed by solvent casting technique which is extremely difficult to scale up industrially. Therefore, there is a need for technology to prepare biodegradable films employing extrusion processing which can be easily scale up industrially. Currently available commercial thermoplastic polymers amenable for extrusion processing such as poly lactic acid (PLA), poly butylene adipate-co-terephthalate) (PBAT) and Poly Hydroxy Alkanoates (PHA) have disadvantage for very high cost.

Preparation of biodegradable films using extrusion processing having comparable cost to that to petroleum based polymers is required. Guar gum is a biopolymer and is widely available in India. In present technology, suitable methodology is described to prepare films from guar gum employing extrusion technology.

TECHNOLOGY IN BRIEF

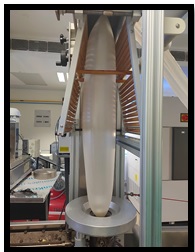

Proposed technology is methodology for preparing biodegradable films using extrusion process. Process involves three steps: 1) Preparation of plasticized guar gum 2) Making compound of plasticized guar gum and poly vinyl alcohol in twin screw extruder 3) Making films by blown film extrusion

RAW MATERIALS

EQUIPMENTS

SPACE

POWER

MANPOWER