The alkaline water electrolyser plant consist of a compact, zero gap, bipolar type configuration cell module stack with high current density porous nickel electrodes. The product gases at the stack exit are conditioned and purified to meet the specific user demands. Demineralised water, electricity and chilled water are the only inputs required for the operation of this plant. The plant is capable of producing high quality hydrogen and oxygen gases and has yielded good performance in sustained long duration operations. The process can be easily scaled up or scaled down to suit the user requirements.

Technology for design, fabrication & installation of Alkaline water electrolysis process technology for on demand on site production of hydrogen and oxygen at a capacity of 10 Nm3/hr Hydrogen & 5 Nm3/hr Oxygen

Technology for design, fabrication & installation of Alkaline water electrolysis process technology for on demand on site production of hydrogen and oxygen at a capacity of 10 Nm3/hr Hydrogen & 5 Nm3/hr Oxygen

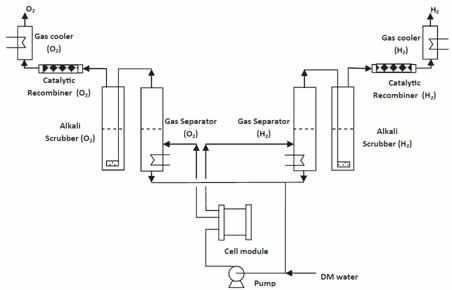

Alkaline water electrolysis plant is a simple one step process wherein water is split using DC electricity into pure hydrogen and oxygen gases. This plant consists of a electrolyser cell module stack integrated with a process skid for purification and conditioning of the product gases as per user's technical specifications.

This green process is simple and includes just one step reaction without generation of any hydrocarbons or other impurities as by-products. The system requires only DM water, chilled water and electricity during operation. It is an energy efficient system and can also serve as an inexpensive import substitution. The plant is very compact enabling high gas production rates in lesser floor space. The production rates can be varied easily for on-demand requirements. The design of plant and SCADA system is such that the operation of plant is safe, reliable and user friendly with minimum manual intervention.

The hydrogen produced by this system can be used in industries like fertilizers, pharmaceuticals, metallurgical operations and food, telecom and fuel cell, etc. It also finds varied applications in laboratory based experiments. The byproduct oxygen can substitute oxygen cylinders in hospitals for reliable and on demand supply of oxygen. It can also be used in emergency shelters employed in hazardous process industries.

EQUIPMENTS

INFRASTRUCTURE

MANPOWER

The manpower required for manufacturing this system should have expertise in electron beam welding, precision machining and assembly of the units.