Many solvents used in chemical laboratory are volatile and hazardous to health. Exposure to these chemicals might affect central nervous system and internal organs, and might cause symptoms such as headache, respiratory tract irritation, dizziness and nausea, known as the Sick Building Syndrome (SBS). Laboratories where these solvents are extensively used need to keep them in sizeable inventory.

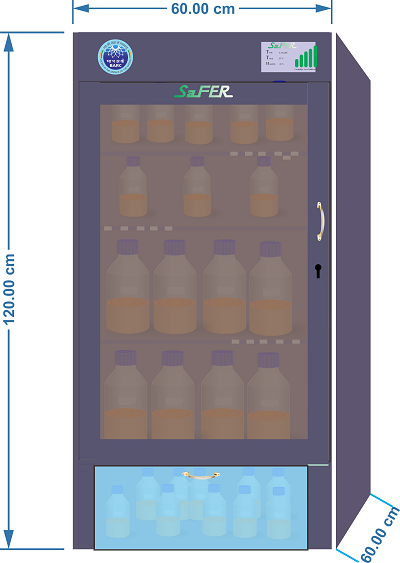

For the purpose of limiting exposure to the hazardous fumes from storage and spillage of chemicals, active reagent cartridges are used for fume extraction from chemical storage cabinet in a laboratory. These cartridges consist of various adsorbents and oxidising agents. These adsorbent materials have specific selectivity for adsorbing volatile fumes and assimilating those fumes in less harmful chemicals. For the demonstration and application of these cartridges, a Storage and Fume Extractor for Reagents (SaFER) product is designed. SaFER is a specially designed storage cabinet with a closed air recirculation mechanism. The fumes released from the stored chemical containers are recirculated through a series of filter cartridges trapping and neutralizing the fumes and pumping the cleaned air back into the storage space. This prevents fume build-up and exposure hazard. The safe storage of volatiles chemicals and thus prevention of the working personnel from exposure is proven to be effective with SaFER.

Specific Active Reagent Cartridges are developed for Fume Extraction from Chemical Storage Cabinet. Chemical fumes can get adsorbed or assimilated by oxidation process into less harmful products in these cartridges. These cartridges consist of various adsorbent and oxidizing agents for removal and assimilation of organic and other hazardous chemical fumes from close environments.

Using this Active Reagent Cartridge technology, a commercially viable product is developed namely “Storage and Fume Extractor for Reagents (SaFER)”.SaFER ensures the safe storage of volatile chemicals and prevents any operating personnel from exposure to these chemicals. It is a specially designed storage cabinet with a flow optimized closed air recirculation mechanism. The fumes released from the containers are recirculated through a series of filter cartridges trapping and neutralizing the fumes and pumping the cleaned air back into the storage space. This prevents fume build-up and thus exposure hazard to users.

Proper handling and safe storage of chemicals is an important practice for any scientific laboratory. Recently, the practice of safe handling of many of the chemicals is being taken into consideration in many research institutions and industries. However, the practice of safe storage of the chemicals is still inadequate. Many solvents used in chemical laboratory are volatile and hazardous to health. Exposure to these chemicals might affect central nervous system and internal organs, and also might cause symptoms such as headache, respiratory tract irritation, dizziness and nausea, known as the Sick Building Syndrome (SBS). Laboratories where these solvents are extensively used need to keep them safely and in sizeable inventory.

Specific Active reagent cartridges are developed for fume extraction from chemical storage cabinets. These cartridges consist of various adsorbents and oxidising agents. These adsorbent materials have specific selectivity for adsorbing volatile fumes and assimilating those fumes into less harmful chemicals by oxidation. For the demonstration of these developed cartridges, a product named Storage and Fume Extractor for Reagents (SaFER) is designed which ensures the safe storage of volatile chemicals and prevents any operating personnel from exposure to them. SaFER is a specially designed storage cabinet with a flow optimized closed air recirculation mechanism. The chemical fumes released from chemical containers are recirculated through a series of filter cartridges trapping and neutralizing these fumes and pumping the cleaned air back into the storage space. This prevents fume build-up in the storage cabinet and thus reduces exposure hazard to the users.

INFRASTRUCTURE

RAW MATERIALS

All the raw materials required are freely available in the Indian local markets

MANPOWER

Minimum three technical person are required viz. one chemist, one sheet metalist/ fitter, and one electronic/instrumentation engineer.